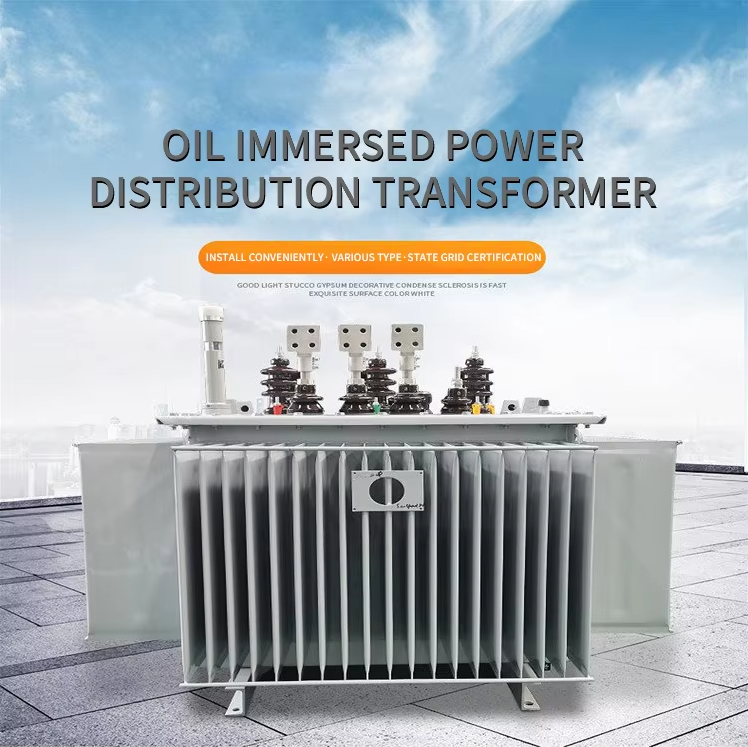

1.Introduction

An oil-immersed transformer is a type of power transformer that uses insulating oil as both a cooling medium and an electrical insulator. It is widely used in power distribution and transmission systems due to its high efficiency, reliability, and ability to handle high voltages.

2.Core Components

- Core: Made of laminated silicon steel to reduce eddy current losses.

- Winding: Primary and secondary coils (copper or aluminum) wound around the core.

- Insulating Oil: Mineral oil or synthetic ester oil for insulation and heat dissipation.

- Tank: Sealed enclosure housing the core, winding, and oil.

- Conservator: An auxiliary tank to accommodate oil expansion/contraction.

- Buchholz Relay: A safety device detecting gas accumulation due to internal faults.

- Cooling System: Radiators or fans to enhance heat dissipation.

3.Working Principle

(1)Electromagnetic Induction

- When AC voltage is applied to the primary winding, it creates an alternating magnetic flux in the core.

- This flux induces a voltage in the secondary winding Faraday’s law of induction .

(2)Insulation & Cooling

- The insulating oil prevents arcing between winding and the grounded tank.

- Oil circulates naturally (or via pumps) to transfer heat from the core/winding to radiators, maintaining optimal temperature. Protection Mechanisms

(3)Buchholz Relay:

- Triggers alarms or disconnects the transformer if gas (from oil decomposition) is detected.

- Pressure Relief Valve: Releases excess pressure to prevent tank rupture.

(4)Advantages

- High efficiency (up to 99%).

- Effective cooling extends lifespan.

- Suitable for high-voltage applications (e.g., 11kV to 400kV).

(5)Applications

Power grids, substations, industrial plants, and renewable energy systems.

Conclusion :Oil-immersed transformers ensure efficient voltage transformation while relying on oil for insulation and cooling. Their robust design makes them indispensable in modern power systems.

Post time: Jun-16-2025